Scale Smarter

Why Now Is the Time to Upgrade Your Extraction System As the cannabis industry prepares for rescheduling and the next wave of regulatory and market

If you’re already running a hydrocarbon extraction lab with a decent compressor and chiller setup, there’s a good chance you’re sitting on untapped potential—and Illuminated Extractors is here to help you unlock it.

We call it The ProJak Hack.It’s the not-so-secret advantage that allows labs already equipped with sufficient thermal horsepower to rapidly scale their post-processing workflow without adding a ton of new infrastructure. How? By plugging in an ISS—Illuminated Isolation Station—and letting your existing compressor/chiller combo power your path to crystal-clear isolate, with no major system overhaul.

Most hydrocarbon extraction systems on the market today are still relying on third-party chillers—expensive, short-lifespan pieces of equipment with built-in obsolescence. These chillers typically top out at 4–5 years before failing, and they aren’t made to be serviced. They’re made to be replaced.

But if you’re running a ProJak DX Compressor System—or any other industrial-grade compressor/chiller setup common in commercial labs—you already have what it takes to power one of the most efficient isolate production vessel on the market. You just didn’t know it yet.

The ISS takes that thermal energy and translates it into better flow control, faster cycles, and fewer breakdowns. Because it’s compressor-compatible, the ISS doesn’t need separate heaters or chillers—it just connects to what you’re already running.

No two labs are alike, and we built the ISS series to reflect that. Whether you’re just entering the isolate game or processing at scale, there’s a system sized for your output goals:

Each ISS comes equipped with Illuminated’s proprietary flow controls and ruggedized vessel jacket construction, built for years of service with minimal maintenance.

The ProJak Hack isn’t just about using what you already have—it’s about eliminating what you don’t need. Labs that switch to the ISS often discover they can offload aging or redundant heater/chiller combos and streamline maintenance schedules across the board. The result?

The Illuminated ISS is plug-and-play compatible with many existing commercial-grade systems—and it’s the fastest way to scale Isolation without overhauling ancillary set-up.

Want to learn more or get matched with the right ISS model?

Contact Us or Download the Cut Sheet to see specs, capacities, and upgrade options.

Why Now Is the Time to Upgrade Your Extraction System As the cannabis industry prepares for rescheduling and the next wave of regulatory and market

If you’re already running a hydrocarbon extraction lab with a decent compressor and chiller setup, there’s a good chance you’re sitting on untapped potential—and Illuminated

Protecting Your Investment in the Long Run When it comes to running an extraction lab, few things are as costly—or avoidable—as unexpected equipment failure. And

When you invest in extraction equipment, you’re not just buying steel and sensors—you’re buying the future of your lab. But not all equipment is built

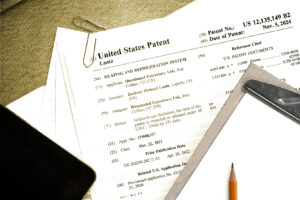

At Illuminated Extractors, we’ve never followed trends—we’ve set them. Now, with our latest innovation officially patented, we’ve secured a new frontier in extraction and refrigeration

The Importance of Annual Field Verifications for Hydrocarbon Extraction Facilities