Scale Smarter

Why Now Is the Time to Upgrade Your Extraction System As the cannabis industry prepares for rescheduling and the next wave of regulatory and market

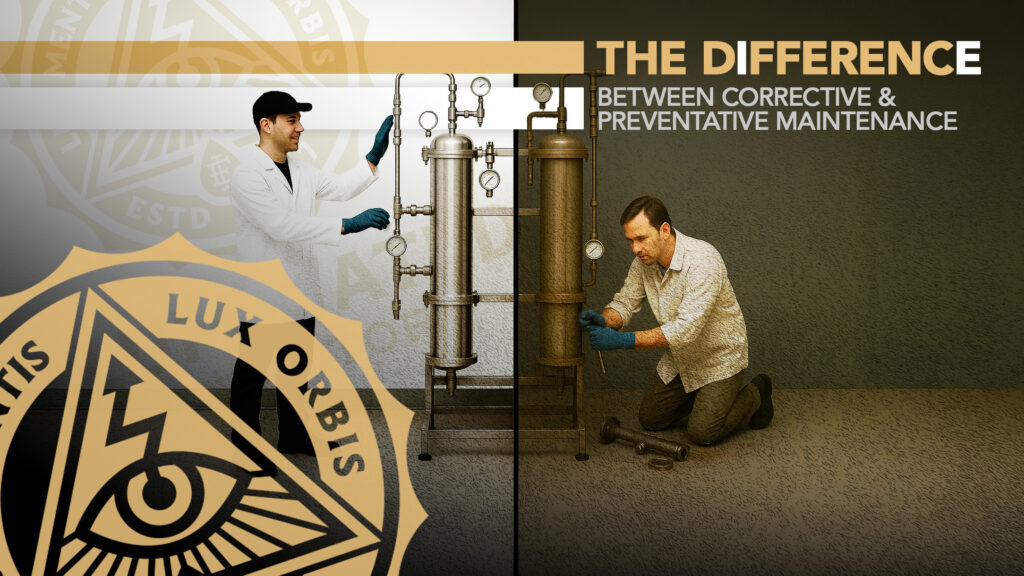

When it comes to running an extraction lab, few things are as costly—or avoidable—as unexpected equipment failure. And yet, many operators treat maintenance like a reaction instead of a strategy. They run their machines until something breaks, usually a chiller or a heater… and by then, it’s too late.At Illuminated Extractors, we’re here to change that mindset. Our systems are built with longevity in mind—designed not to be replaced every few years, but sustained for decades through smart, scheduled upkeep. That’s the difference between preventive maintenance and corrective maintenance, and understanding it could save your lab thousands of dollars—and countless hours of downtime.

Preventive Maintenance (PM) refers to routine inspections, cleaning, part replacements, and performance checks that are performed on a regular schedule to prevent failure before it happens.

With Illuminated Extractors systems, particularly those enrolled in the customized SWAPBOX Sustainment Program, those actionable items include:

Just like changing the oil in your vehicle, regular PM keeps your system humming, ensures peak efficiency, and prevents production-stopping failures.

Corrective Maintenance means waiting until something breaks… and then scrambling to fix it.

In the world of hydrocarbon extraction, this often looks like:

Heaters and chillers in our particular industry inevitably have short lifespans. Chillers, for example, typically have a 4–5 year usable life before needing complete replacement. That’s planned obsolescence baked into your business model.By contrast, our compressor-based refrigeration system was built to be maintained, not replaced. That’s a core principle of industrial equipment in the oil & gas sector—where our compressor technology comes from.

Most extraction machines on the market rely on third-party chillers and heaters—equipment with fragile components and limited longevity. Once they begin to fail service is expensive and replacement is inevitable.

The Illuminated approach is different:

Your compressor is the heartbeat of your system. With proper care, it can run indefinitely. Why throw away thousands every few years when you could maintain one high-performance component for decades?

Let’s talk numbers.

Chillers often last 4-5 years, at best. Depending on the manufacturer and needs, the cost can be significant to say the least, and many labs are feeling that, right now.

Now compare that to preventive maintenance using a compressor that’s BUILT TO LAST! A few hours of proactive labor can eliminate the need to replace your heaters and chillers for thermal control, saving you time and money. That’s ProJak.

Preventive maintenance doesn’t just protect your equipment, it protects your bottom line.

Preventive maintenance is about more than just equipment. It’s about building a resilient operation. One that doesn’t halt when something goes wrong. One that plans, instead of panics.

At Illuminated Extractors, our philosophy is simple: Buy it once. Maintain it forever.

If you’re unsure how to set up a preventive maintenance schedule, or want a walkthrough on the core points of compressor care, please reach out. Our technical team is here to help you sustain your system, not just sell you another one.

Download our Preventive Maintenance Checklist or schedule a consult with our team to get ahead of the curve.

Let’s keep your system running smooth for this year and the next.

Why Now Is the Time to Upgrade Your Extraction System As the cannabis industry prepares for rescheduling and the next wave of regulatory and market

If you’re already running a hydrocarbon extraction lab with a decent compressor and chiller setup, there’s a good chance you’re sitting on untapped potential—and Illuminated

Protecting Your Investment in the Long Run When it comes to running an extraction lab, few things are as costly—or avoidable—as unexpected equipment failure. And

When you invest in extraction equipment, you’re not just buying steel and sensors—you’re buying the future of your lab. But not all equipment is built

At Illuminated Extractors, we’ve never followed trends—we’ve set them. Now, with our latest innovation officially patented, we’ve secured a new frontier in extraction and refrigeration

The Importance of Annual Field Verifications for Hydrocarbon Extraction Facilities