Scale Smarter

Why Now Is the Time to Upgrade Your Extraction System As the cannabis industry prepares for rescheduling and the next wave of regulatory and market

Whether you’re a seasoned professional or new to the world of extraction labs, it’s crucial to avoid common pitfalls that can lead to costly errors or safety hazards. In this brief guide, we’ll go over the most frequent mistakes organizations make with extraction lab equipment and share practical tips to steer clear of them. Let’s dive in!

Regular maintenance is crucial for keeping all extraction lab equipment running smoothly. Ignoring this can lead to unexpected breakdowns and costly repairs. For instance, equipment like chillers and heaters require constant maintenance, especially given the demanding nature of cannabis and hemp. When these systems malfunction, it can halt entire lab operations, just as poor maintenance can create a dangerous environment due to leaking gases in labs. To stay on track, create a maintenance schedule that outlines routine checks and preventative measures.

Neglecting parts that wear out such as seals, gaskets, and bearings can lead to equipment failure. Ensuring you have a redundancy, like Illuminated Extractors’ SWAPBOX, labs can prevent unnecessary, costly downtime. Furthermore, staying on top of maintenance not only extends the lifespan of equipment but also improves overall lab safety, which is paramount in avoiding damages and incidents.

Calibration is a key factor in obtaining accurate results in any laboratory. Without proper calibration, even the most dependable pieces of equipment can yield unreliable results, jeopardizing the integrity of your extraction operations. Regular calibration should be part of your maintenance protocol, tailored to the specifics of each piece of equipment involved.

Calibration enhances accuracy and alleviates some of your lab’s safety liability caused by improper readings. By employing the right calibration services and software, you can significantly improve the safety and efficiency of your lab, ensuring consistent quality in your extracts.

Training isn’t just a one-time event or box to tick—it’s an ongoing commitment to safety and efficiency. It’s essential to ensure that your team understands each function of the extraction lab equipment – after all, well-informed staff can catch errors before they become critical. Training programs and attention to hiring the right candidates can reduce the chances of mistakes and accidents, keeping your operations running smoothly and safely.

Competent training should cover the specifics of operating each type of extractor, like open-loop and closed-loop systems. By empowering your staff with this knowledge, they are better equipped to manage the equipment effectively and respond to potential issues before escalation. This could mean the difference between a seamless operation and a catastrophic error that could be costly both in time and resources.

Proper ventilation is critical in extracting labs for both safety and efficiency. The AHJ (authority having jurisdiction) will have different expectations depending on where your lab is located. By now, all certified and compliant machines are housed in a C1D1 booth fitted with ventilation and safety mechanisms to keep operators safe. Failing to ensure appropriate ventilation can lead to harmful consequences, including an increased likelihood of fires and explosions, as explored in a detailed analysis of accidents in labs using volatile chemicals. Proper facility design ensures the safe handling of flammable solvents and gases, reducing accident risks in labs.

Whether handling solvents or working with extractors, understanding proper safety procedures is essential. Comprehensive safety protocols help mitigate risks associated with extractor malfunctions, spills, and any hazard found in the extraction lab. Check that your lab meets necessary safety standards, as regulators take such requirements seriously. If you’re handling hazardous materials, ensure standard operating procedures are followed meticulously to prevent accidents and ensure compliance.

Documentation serves as the backbone of any extraction operation, providing a detailed account of processes, results, and protocols. Lacking thorough records can lead to repeated mistakes, undefined accountability, and inefficiencies. Document tasks meticulously, from equipment maintenance to extraction techniques, ensuring traceability and accountability within the lab. This approach also enhances your ability to maintain regulatory compliance, as records can be presented during audits.

Quality control ensures the consistency and safety of your products. Discover ways to enhance QC measures in your lab operations.

Quality control processes in extraction labs go beyond merely checking products. They are about maintaining standard operational procedures and product consistency, safeguarding your brand reputation. Skipping or under-prioritizing these measures can result in defective products hitting the market, damaging consumer trust. Regular internal and third-party testing and verification are vital in ensuring product integrity and compliance with industry regulations.

Why Now Is the Time to Upgrade Your Extraction System As the cannabis industry prepares for rescheduling and the next wave of regulatory and market

If you’re already running a hydrocarbon extraction lab with a decent compressor and chiller setup, there’s a good chance you’re sitting on untapped potential—and Illuminated

Protecting Your Investment in the Long Run When it comes to running an extraction lab, few things are as costly—or avoidable—as unexpected equipment failure. And

When you invest in extraction equipment, you’re not just buying steel and sensors—you’re buying the future of your lab. But not all equipment is built

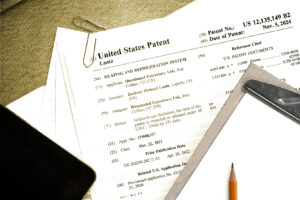

At Illuminated Extractors, we’ve never followed trends—we’ve set them. Now, with our latest innovation officially patented, we’ve secured a new frontier in extraction and refrigeration

The Importance of Annual Field Verifications for Hydrocarbon Extraction Facilities