Scale Smarter

Why Now Is the Time to Upgrade Your Extraction System As the cannabis industry prepares for rescheduling and the next wave of regulatory and market

In the rapidly evolving and often chaotic world of cannabis and hemp processing, flexibility is more than a convenience—it’s becoming essential. Retail prices have leveled out in many states while consumers’ expectations for quality remain high, resulting in a delicate balance to maintain for many laboratories. Generally, higher-quality products require additional, more costly ancillary equipment and/or reliance on consumables, such as CO2 or NO2.

Regarding hydrocarbon extraction equipment, no manufacturer is more adaptable than Illuminated Extractors. While other manufacturers design their systems from behind a desk, our designer spends countless hours in the lab, solving the real-world problems inherent in the “desk-designed” machines of the first generation. We understood that every day in the lab presents new variables and challenges: ancillary equipment failures, varying biomass inputs, and unpredictable shifts in customer demand. That’s why we developed our hydrocarbon extraction equipment with a level of self-containment, user-serviceability, and fluidity unmatched in the industry.

Imagine running your machine for two or three completely different products on the same day. With Illuminated Extractors, it’s not only possible—it’s being done by many of the labs who have sunset their first-generation equipment and started to RUN DIFFERENT. Our advanced hydrocarbon extraction equipment allows operators to independently heat and chill columns across the machine, giving them precise control over every stage of the process. This means you can process biomass for a full-spectrum extract in the morning and isolate production by the afternoon—each run tailored to the exact needs of the material and the end product.

This adaptability is essential for handling variable input biomass, which can differ significantly in moisture content, terpene profile, cannabinoid potency, remediation required, etc. While other systems are constrained by rigid heater and chiller configurations, Illuminated Extractor’s ProJak DX Refrigeration and FASTFLOW Solvent Cycling Technology give your operators total control when your variables inevitably change.

Illuminated Extractors’ systems don’t just offer flexibility—they redefine reliability, while offering more machine in place of burdensome and expensive chillers. By integrating independent column heating and chilling with ProJak DX Refrigeration, we’ve eliminated the need for traditional heaters, excessive chillers, and much of the typical post-processing equipment. The capital normally spent on heaters and chillers can now be utilized to make your machine bigger, faster, or BOTH! This streamlined approach significantly reduces operational costs and energy consumption while minimizing downtime. Operators can adjust on the fly like never before, optimizing parameters based on biomass characteristics or shifting product goals—all without missing a beat.

In a market where consumer preferences can change with little to no warning, having adaptable hydrocarbon extraction equipment is a significantly underrated competitive advantage. Whether you’re producing boutique, terpene-rich extracts or scaling up to create pharmaceutical-grade high-purity isolates, Illuminated Extractors’ systems are designed to navigate the unforeseen shifts that may be needed with unmatched reliability, speed, and efficiency.

Our ability to process inline, adjust to any variable, and deliver consistent results sets us apart. However, it’s more than flexibility—it’s about hydrocarbon extraction equipment that evolves with your business.

Ready to discuss your lab’s future? Contact us to learn how Illuminated Extractors can transform your lab’s efficiency and versatility.

Why Now Is the Time to Upgrade Your Extraction System As the cannabis industry prepares for rescheduling and the next wave of regulatory and market

If you’re already running a hydrocarbon extraction lab with a decent compressor and chiller setup, there’s a good chance you’re sitting on untapped potential—and Illuminated

Protecting Your Investment in the Long Run When it comes to running an extraction lab, few things are as costly—or avoidable—as unexpected equipment failure. And

When you invest in extraction equipment, you’re not just buying steel and sensors—you’re buying the future of your lab. But not all equipment is built

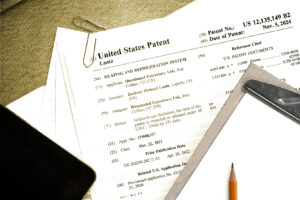

At Illuminated Extractors, we’ve never followed trends—we’ve set them. Now, with our latest innovation officially patented, we’ve secured a new frontier in extraction and refrigeration

The Importance of Annual Field Verifications for Hydrocarbon Extraction Facilities