7 Common Extraction Lab Equipment Mistakes and How to Avoid Them

Avoid costly errors with our guide on extraction lab equipment in 7 Common Extraction Lab Equipment Mistakes and How to Avoid Them’.

Botanical extraction equipment requires regular maintenance. Extractors and extraction company CEOs should know the production volume for each machine, understand which components need cleaning, keep a maintenance log, and always have extra extraction parts on hand.

When your team is working to roll out retail-ready extracts that will establish a foothold in the crowded botanical marketplace, the last thing you want is poorly maintained equipment creating bottlenecks along the production line. In fact, regular cleaning and maintenance is the key to ensuring optimal performance from your hydrocarbon extraction equipment.

With so many crucial components in all extraction runs, it’s imperative that you zero in on a maintenance plan, take the necessary steps to keep equipment running properly, and avoid downtime. But where does one start?

Well, if you are a botanical extractor or a CEO of an extraction company, the best place to start is with the basic do’s and don’ts of extraction equipment maintenance. In this guide, you’ll learn what you absolutely must focus on and what you should steer clear of at all costs.

Many of your most important business decisions will stem from the production volume of each machine. Production volume, or production capacity, is the maximum possible output of a piece of extraction equipment. Often measured in pounds per hour or per day, production volume knowledge improves planning and scheduling, allowing you to calculate accurate lead times and cash flow.

Production volume can also clue you in to a machine’s need for maintenance. Let’s say your extraction equipment typically runs up to 100 pounds of product per hour. If there is a sudden and sustained dip in that number, there’s a good chance your machine needs maintenance. Understand the production volume of your machine beginning with your very first extraction run, and keep an eye out for any deviation from that baseline in subsequent extractions.

Keeping a clean work environment free of dust and other microscopic debris gives you an extra layer of protection against any impurities in your products. What’s more, a clean work environment can be used in your marketing materials to give consumers a behind-the-scenes look at your spotless facility and assure them that your products are as pure as advertised.

But when it comes to keeping the extraction lab clean, not all vacuums are created equal. In fact, there are certain vacuum cleaners that are strictly not appropriate for use in lab and manufacturing facilities. Shop-style vacuums, for example, do not boast high-quality filtration, and they are constructed with materials that can be deemed unsanitary. These non-classified vacuums simply aren’t designed to handle the rigorous cleaning demands of botanical extraction equipment.

Sanitation processes, such as Sanitation Standard Operating Procedures (SSOP) and overarching Good Manufacturing Practices (GMP), are key to the safe production of extracts. For your extraction facility, seriously consider outfitting your team with “dry” superheated steamers to clean tools and surfaces, industrial vacuum systems to collect debris, and HVAC cleaning and sanitation equipment.

Extraction equipment consists of a long list of individual components that all require different levels of attention for maintenance and sanitation. Get to know each individual piece of equipment and how each one functions in order to gain a better understanding of how to perform routine maintenance. These components include:

You and your team should observe every corner of the extraction facility. Take special note of any visible wear and tear, but also keep a general log of when each piece of equipment was last cleaned and when the next scheduled maintenance should take place. Hydrocarbon extraction equipment—including butane and propane—performs better when facility managers practice top-tier attention to detail.

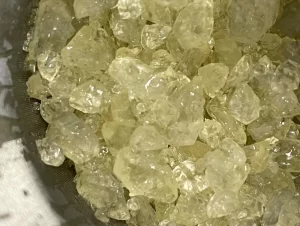

One type of maintenance happens at the end of each extraction run—and that’s the solvent purge. When you put plant material through extraction equipment with the goal of having a pure botanical extract on your hands, it’s normal for certain levels of residual solvent to remain in your end product.

However, just because residual solvent is normal, it doesn’t mean consumers want a dose of butane and propane with their extracts or essential oils. What’s more, when your product goes through the required third-party lab testing, any detection of residual solvents could stop your march to the marketplace dead in its tracks.

Vacuum purging, also known as outgassing, is performed using a vacuum oven that evaporates residual butane and propane from botanical extracts. The result is a BHO that is clean, flavorful, and aromatic without any of that harsh butane odor or taste. Delete this

After you’ve figured out what needs to be cleaned and when, devise a maintenance calendar for each extraction system in your facility. This helps you keep track of all the times routine maintenance was performed and ensures regular care remains part of your facility’s standard operating procedure.

Make sure each extraction system has a unique maintenance log and cleaning schedule, and see that all operators record each maintenance activity in their own logbook for future reference. For example, a comprehensive logbook tracks instances of maintenance work on gas compressor pumps or solvent tanks, checking and recording oil levels and the performance of pressure valves. Documented findings can note noise levels or vibration changes, both of which could signal a larger problem within the extraction system.

This “don’t” is one that should be included in the handbook of any facility, no matter what they are manufacturing. However, in the botanical extract industry, security is especially important. Even with legalization becoming a reality in a growing number of states, this is still a controlled substance under federal law.

As such, you must follow a strict set of security protocols to ensure you remain fully compliant with your local regulatory body. To prevent unauthorized personnel from accessing your extraction facility, deploy the following security measures:

Extraction equipment used to process the plant is highly complex, involving many moving parts and often volatile chemicals. This underscores the need for comprehensive employee training, which not only increases production but also offers a stronger adherence to safety protocols.

What training do extraction employees need?

Comprehensive training for all new employees—and procedure refreshers for existing employees—guarantees an educated team of professional extractors. This is invaluable for extraction facilities, especially when you consider how employee errors can cause downtime.

As we’ve previously mentioned in this article, extraction machinery is complex, with many different moving parts. Should a problem arise in even the smallest area, it can trigger a domino effect, leading to a catastrophic breakdown, possible safety threats, or even a seriously diminished yield.

During your regular maintenance, you should pay close attention to weak or damaged valves, seals, and connections. These are some of the most active points in any extraction system, and they experience more wear and tear than other components.

Weak valves, seals, and connections can cause solvent to leak from the system. This reduces yield and can have an immediate impact on your ability to make a profit.

Addressing a problem before it becomes a problem is a talent that separates successful ventures from their unsuccessful counterparts. This is especially true in a market as crowded as the current botanical extract industry.

Make it a point to anticipate the typical maintenance needs for parts and materials that tend to wear out over time. This includes parts such as valves, o-rings, and belts, as well as wear parts like oil, filters, and coolant. Keep a stock of spare parts in your facility and replenish as needed. When you keep these supplies on-site, it allows for quick extraction equipment repairs. This helps avoid downtime and keeps your extraction system humming along.

Illuminated Extractors builds equipment for large-scale hydrocarbon extraction. Connect with us today and learn how to maintain our purpose-built, long-lasting extraction equipment.

Avoid costly errors with our guide on extraction lab equipment in 7 Common Extraction Lab Equipment Mistakes and How to Avoid Them’.

Discover how commercial extraction equipment is transforming the industry in our blog ‘How Commercial Extraction Equipment is Revolutionizing the Industry’.

Discover the essential features to seek in premium BHO extractors in our guide ‘The Top 7 Features to Look for in High-Quality Essential Oil Extractors’.

Streamline your processes with BHO extraction equipment featured in ‘Streamline Your Workflow with Advanced BHO Extraction Equipment.

Illuminated Extractors Cost Savings

Illuminated Extractors Cost Savings

It’s time to start your extraction journey with Illuminated Extractors.

Certified in all 50 States

All Illuminated Extractors extraction models have received Technical Report Certification authored by Pressure Safety Inspectors (PSI). All models have been peer-reviewed for Safety and compliance in all 50 states. Please contact us for more information about certifications for your local AHJ.

Illuminated Extractors LTD – All Rights Reserved. Copyright © 2017-2024. Privacy Policy | Terms & Conditions